China wholesale Thick Liquid Hot Filling Machine - Push Type Heating Mixing Mascara Filling Machine – Eugeng

China wholesale Thick Liquid Hot Filling Machine - Push Type Heating Mixing Mascara Filling Machine – Eugeng Detail:

Model EGMF-02 with heating and mixing mascara filling machine is a semi-automatic filling and capping machine design for the production of high viscous cosmetic liquid,such as lip gloss,mascara eyeliner,gel,cream,suitable for filling both liquid and high viscosity paste.Heating and mixing can turn on/off based on needs.

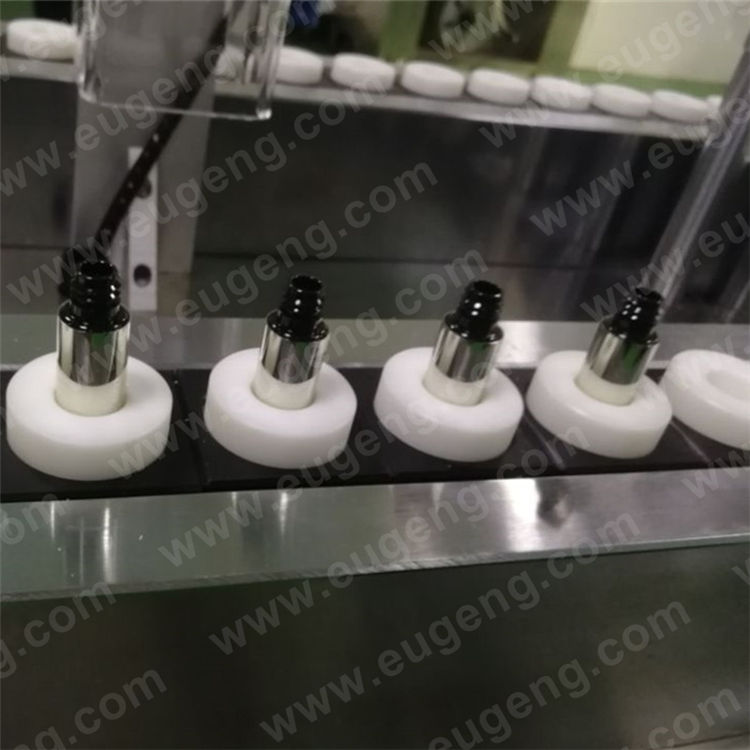

Lip gloss

Mascara

Eyeliner

· 1 set 30L pressure tank with inner plug for high viscosity materials

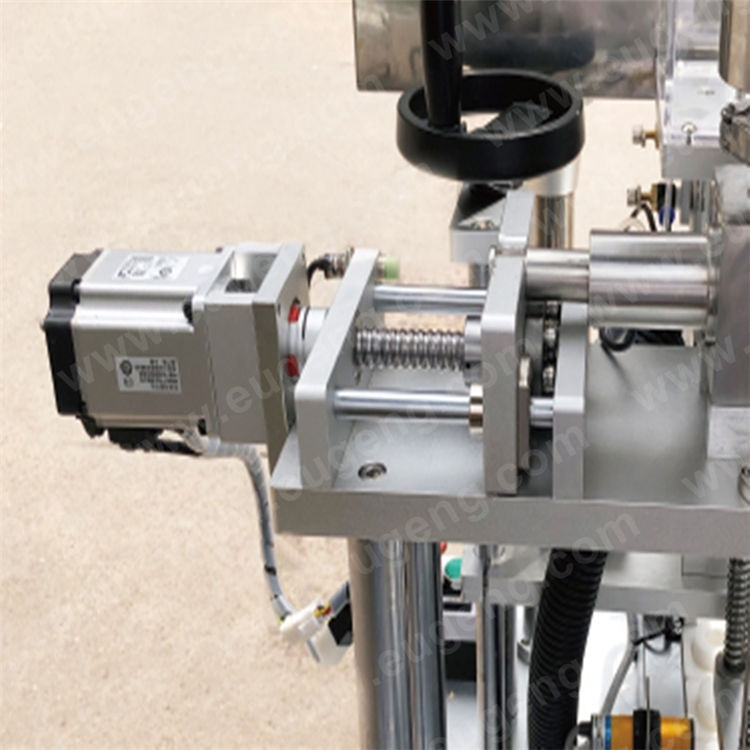

· Piston controlled dosing pump, and with servo motor driving , filling while tube moving down

. Machine with sucking back function so that prevent dripping

· Accuracy +/-0.5%

· Filling unit designed for easy strip-down cleaning and re-assembly to facilitate quick change over

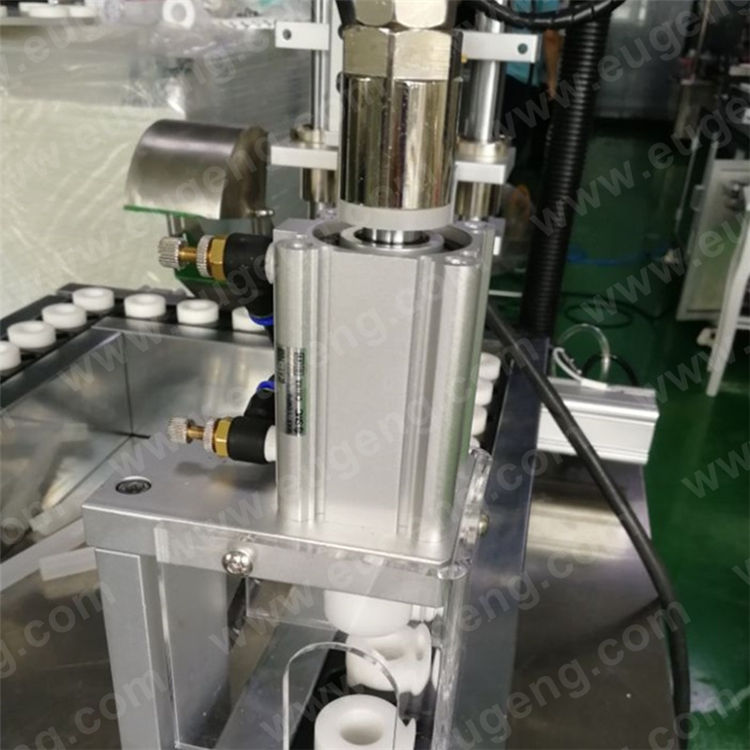

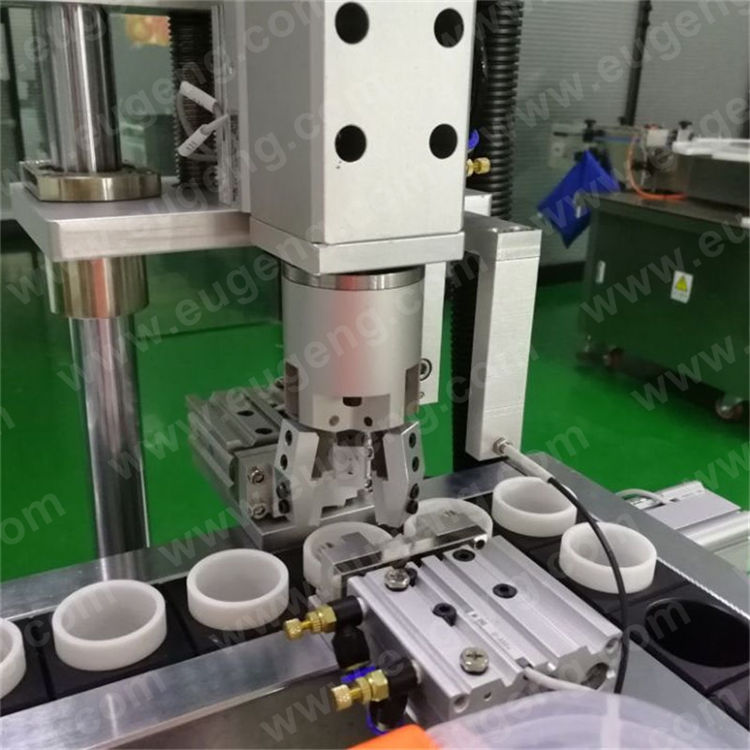

· Servo-motor capping unit with adjusted torque,capping speed and capping height also adjustable

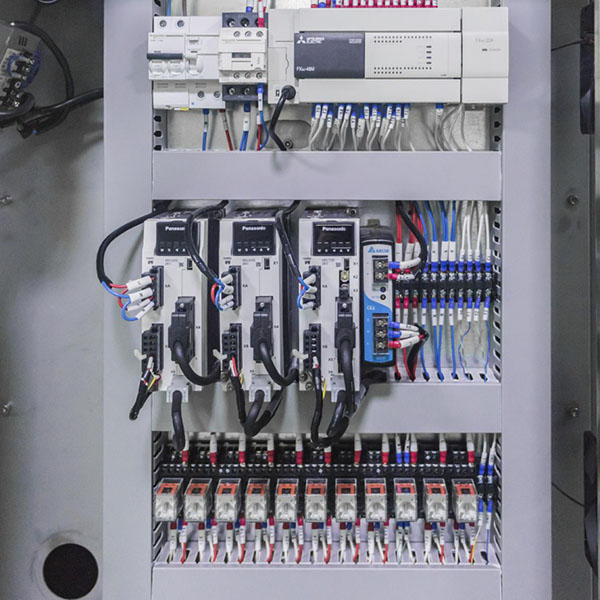

Touch screen control system with Mitsubishi brand PLC

Servo motor Brand:Panasonic Original: Janpan

Servo motor control the capping , and torques can be adjusted , and reject rate is less than 1%

Heating mixing mascara filling machine wide application :

Widely used for filling high viscosity cosmetic liquid, cream, gel, lip gloss,mascara,eyeliner etc..

Heating mixing mascara filling machine puck customized

POM(according to the diameter of bottle)

Heating mixing mascara filling machine Capacity

30-35pcs/min

| Model | EGMF-02 with heater and mixer |

| Production type | Push Pucks |

| Output capacity/hr | 1800-2100pcs/h |

| Control type | Servo motor&Air Cylinder |

| No.of Nozzle | 1 |

| Number of pucks | 49 |

| Vessel volume | 30L/set |

| Display | PLC |

| No.of operator | 2-3 |

| Power consumption | 7.5kw |

| Dimension | 1.5*0.8*1.9m |

| Weight | 450kg |

| Air input | 4-6kgf |

Push table

Sensor for checking tubes no tube no filling

Filling nozzle with guider prevent nozzle broken

Two Pressure tanks with plug for high viscosity bulk with heated and mixer

Filling system fast cleaning and reassembly

Filling with servo motor driven, volume adjustable

Pressing wiper with cylinder,can turn on/off

Servo motor capping , torques can be adjustable

Capping head height can be easily adjusted

Different size tube just need change pucks

PLC MITSUBISHI

Servo Motor Panasonic

Pneumatic is SMC

Product detail pictures:

Related Product Guide:

The consumer fulfillment is our primary goal. We uphold a consistent level of professionalism, top quality, credibility and service for China wholesale Thick Liquid Hot Filling Machine - Push Type Heating Mixing Mascara Filling Machine – Eugeng , The product will supply to all over the world, such as: Puerto Rico, Ethiopia, Azerbaijan, Our solutions have national accreditation requirements for qualified, good quality products, affordable value, was welcomed by individuals all over the world. Our products will continue to improve inside the order and appear forward to cooperation with you, Definitely should any of those goods be of curiosity to you, be sure to letus know. We'll be satisfied to supply you a quotation up on receipt of the detailed needs.

We have been engaged in this industry for many years, we appreciate the work attitude and production capacity of the company, this is a reputable and professional manufacturer.