Factory supplied Cosmetic Thick Cream Filling Machine - Push Type Mascara Filling Machine – Eugeng

Factory supplied Cosmetic Thick Cream Filling Machine - Push Type Mascara Filling Machine – Eugeng Detail:

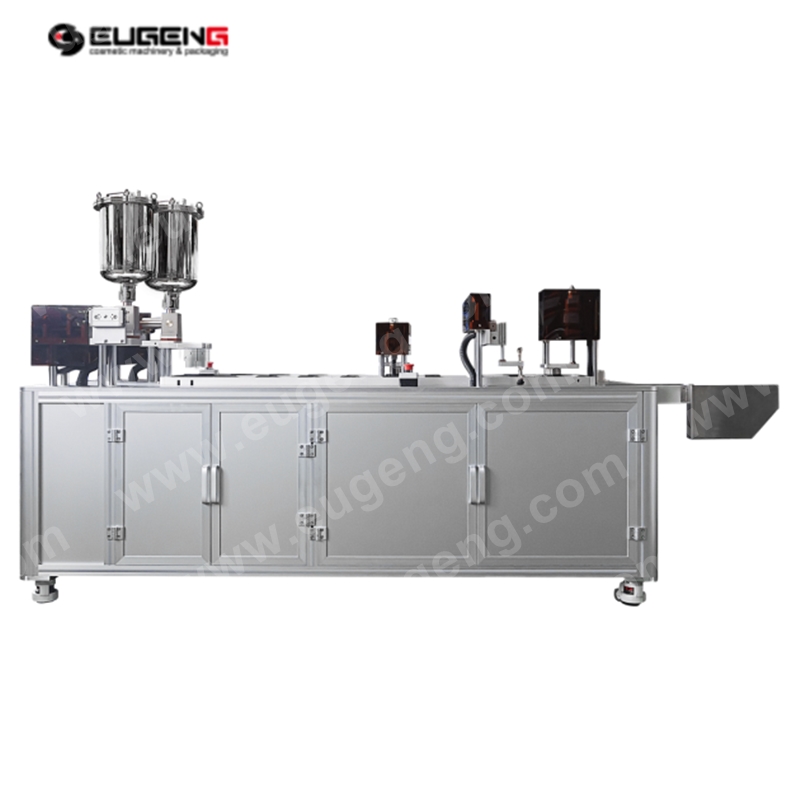

Model EGMF-02 mascara filling machine is a semi-automatic filling and capping machine design for the production of lip gloss,mascara eyeliner,nail polish,cosmetic liquid foundation,perfume card,teeth whitening pen etc..suitable for filling both liquid and high viscosity paste gel ,filling and capping round bottles,square bottles and some irregular bottles.

Lip gloss

Mascara

Eyeliner

·1 set 30L pressure tank with inner plug for high viscosity materials

· Piston controlled dosing pump, and with servo motor driving , filling while tube moving down

. Machine with sucking back function so that prevent dripping

·Accuracy +/-0.5%

·Filling unit designed for easy strip-down cleaning and re-assembly to facilitate

quick change over

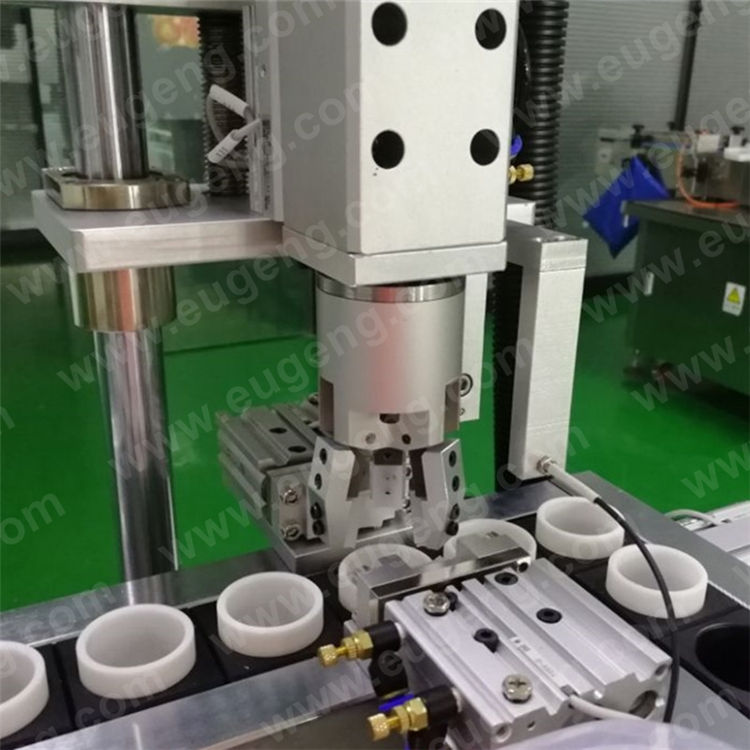

·Servo-motor capping unit with adjusted torque,capping feed and capping height also adjustable

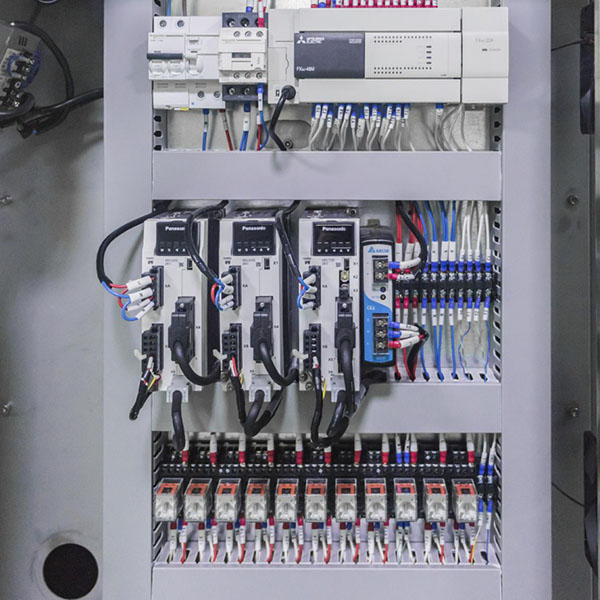

·Touch screen control system with Mitsubishi brand PLC

Servo motor Brand:Panasonic Original: Janpan

Servo motor control the capping , and torques can be adjusted , and reject rate is less than 1%

mascara filling machine wide application :

Widely used for filling lip gloss,mascara,eyeliner,nail polish,cosmetic liquid foundation,serum,essential oil,perfume,teeth whiten gel etc..

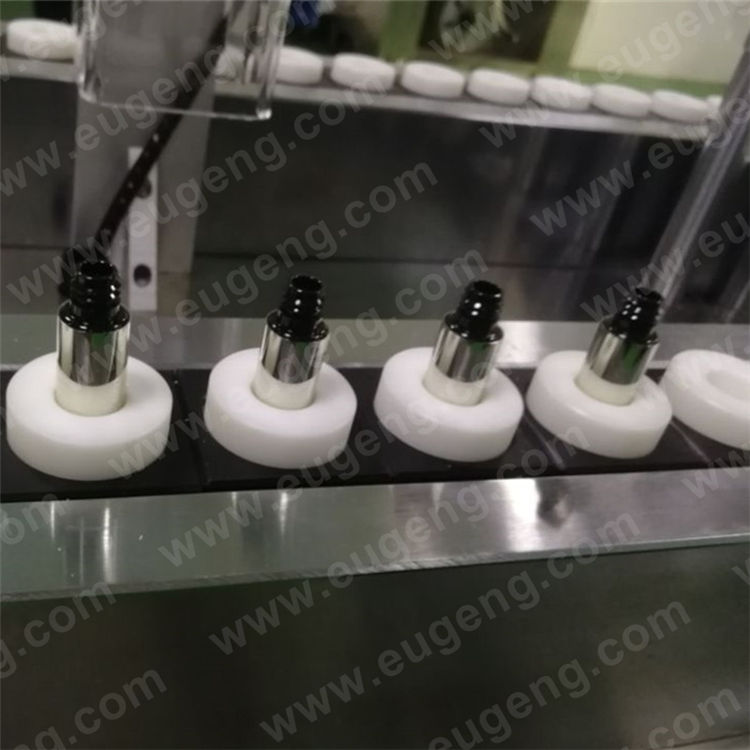

mascara filling machine Mold customized

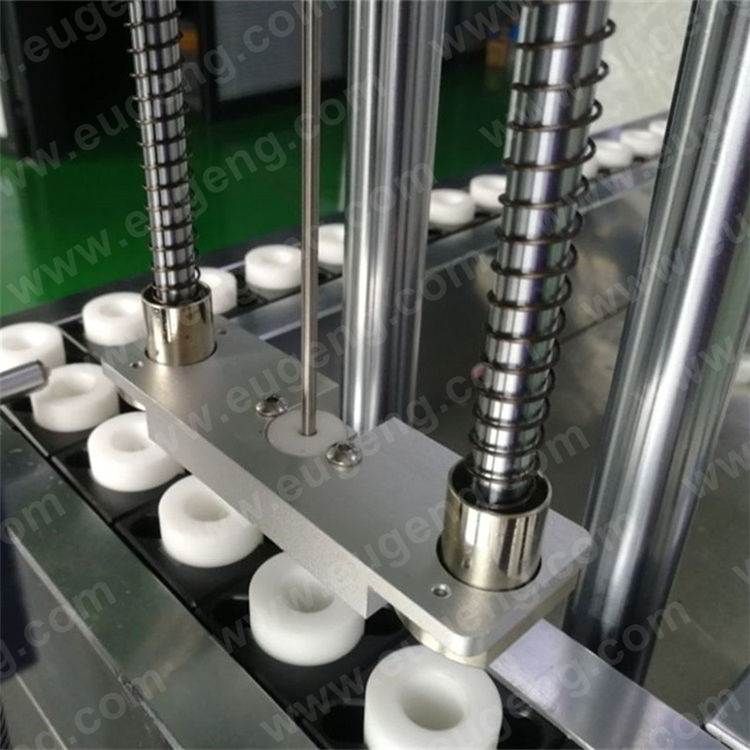

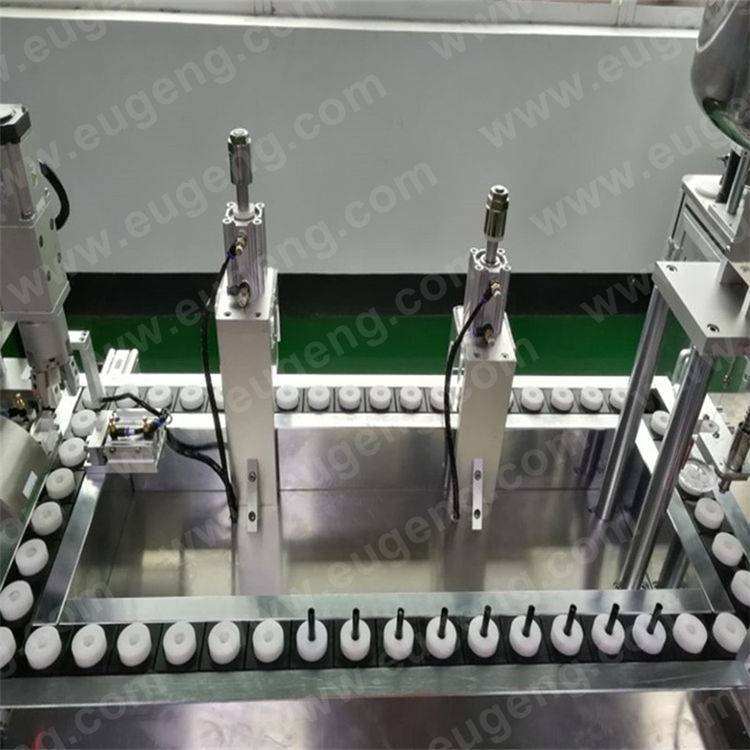

Nylon holder(according to the diameter of bottle)

Lip gloss mascara filling machine Capacity

30–35pcs/min

| Model | EGMF-02 |

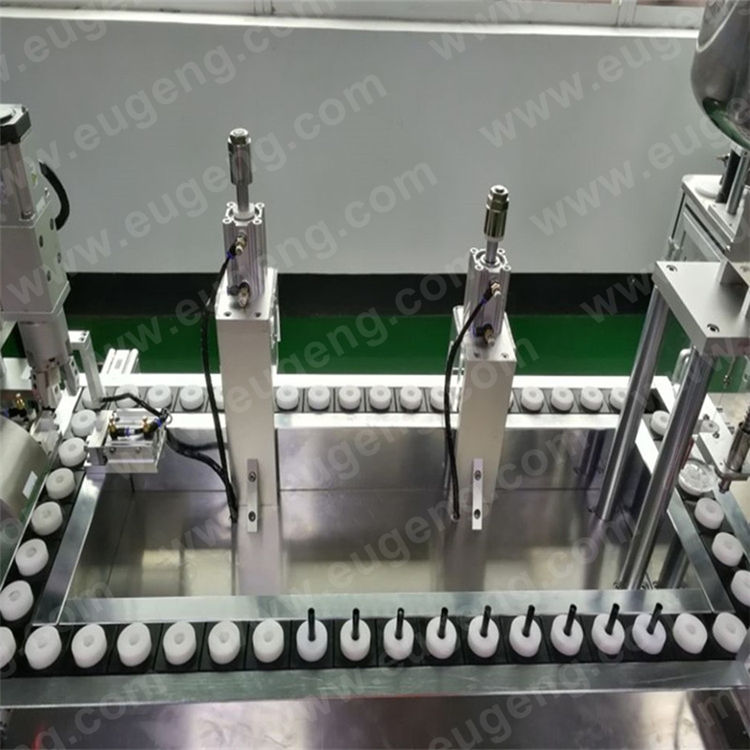

| Production type | Push Pucks |

| Output capacity/hr | 1800-2100pcs/h |

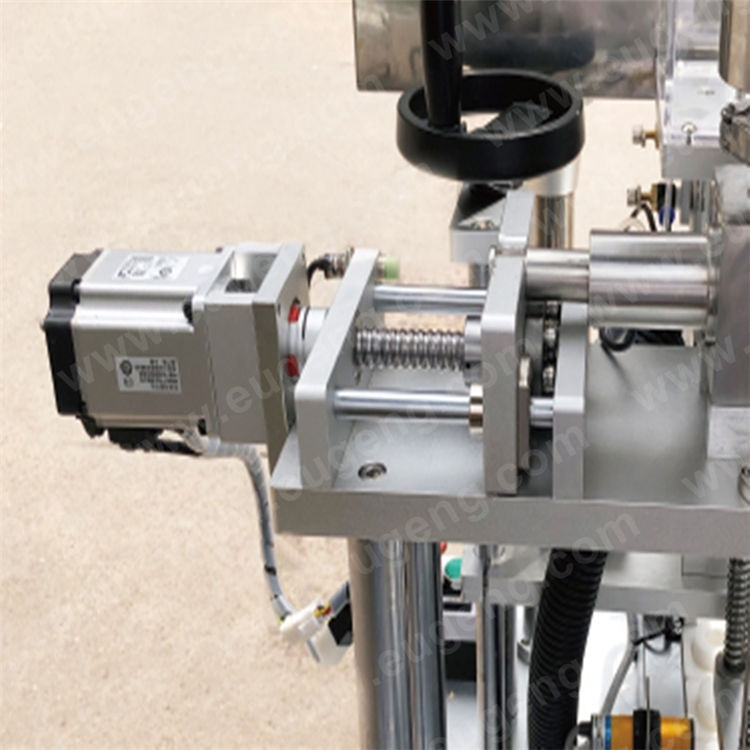

| Control type | Servo motor&Air Cylinder |

| No.of Nozzle | 1 |

| Number of pucks | 49 |

| Vessel volume | 30L/set |

| Display | PLC |

| No.of operator | 2-3 |

| Power consumption | 2.5kw |

| Dimension | 1.5*0.8*1.9m |

| Weight | 450kg |

| Air input | 4-6kgf |

Push Table

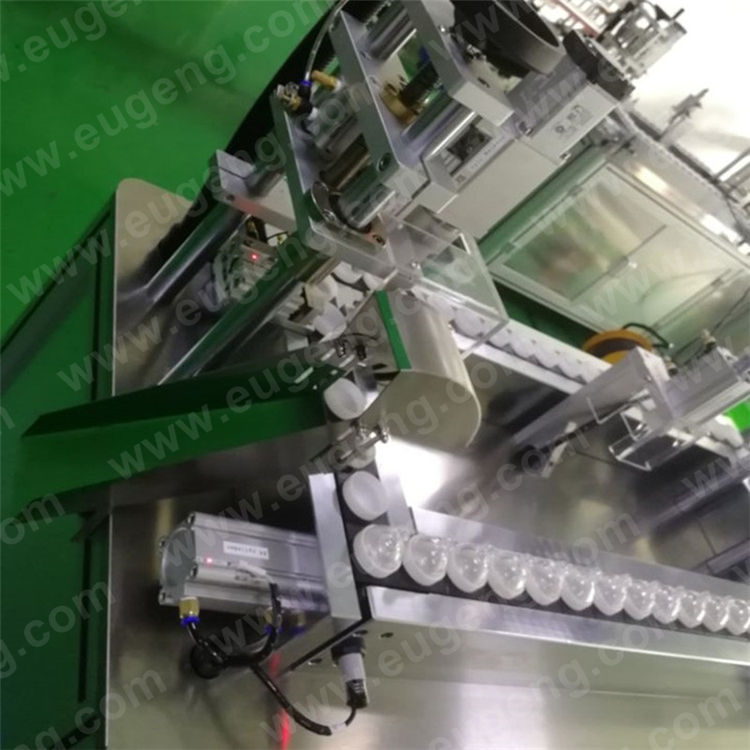

Sensor for checking tubes no tube no filling

Filling nozzle with guider prevent nozzle broken

Pressure tank with plug for high viscosity bulk

Filling system fast cleaning and reassembly

Filling with servo motor driven, volume adjustable

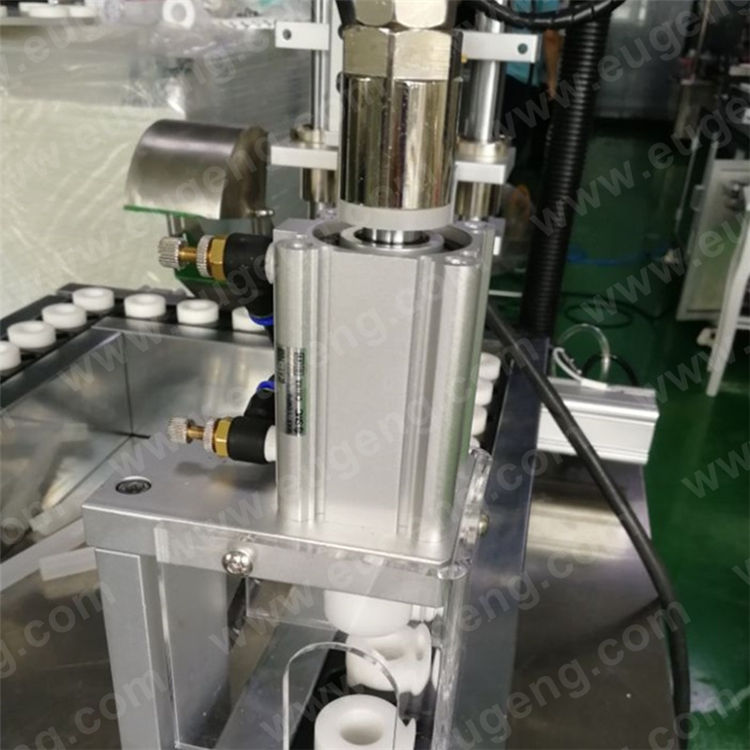

Pressing wiper with cylinder,can turn on/off

Servo motor capping , torques can be adjustable

Capping head height can be easily adjusted

Different size tube just need change pucks

Filling stainless ball

PLC Mitsubishi

Servo Motor Panasonic

Pneumatic is SMC

Product detail pictures:

Related Product Guide:

Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs for Factory supplied Cosmetic Thick Cream Filling Machine - Push Type Mascara Filling Machine – Eugeng , The product will supply to all over the world, such as: Brisbane, Florida, Slovenia, Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We are looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

This is a very professional wholesaler, we always come to their company for procurement, good quality and cheap.