Good Quality Silicone Mold Lipstick Production Line - Nail Polish Filling And Capping Machine – Eugeng

Good Quality Silicone Mold Lipstick Production Line - Nail Polish Filling And Capping Machine – Eugeng Detail:

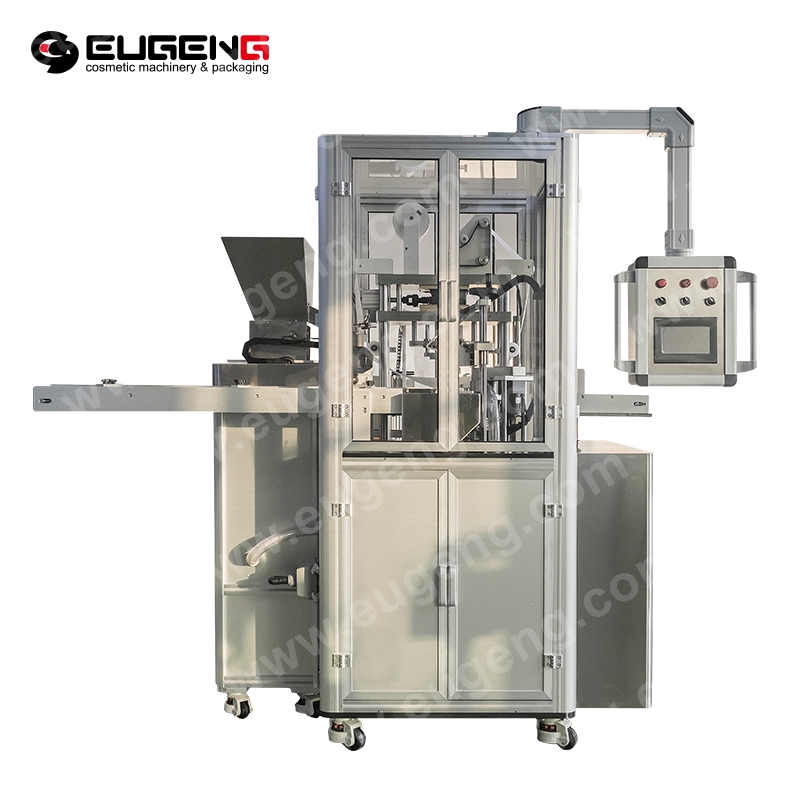

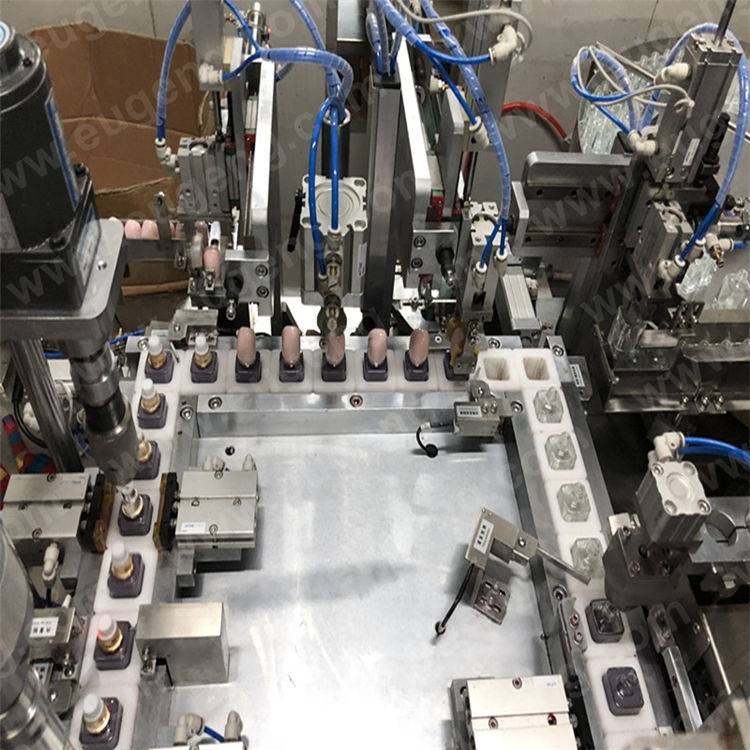

Model EGNF-01A nail polish filling and capping machine is an full automatic nail polish machine designed for the production of nail polish,gel polish

Nail polish

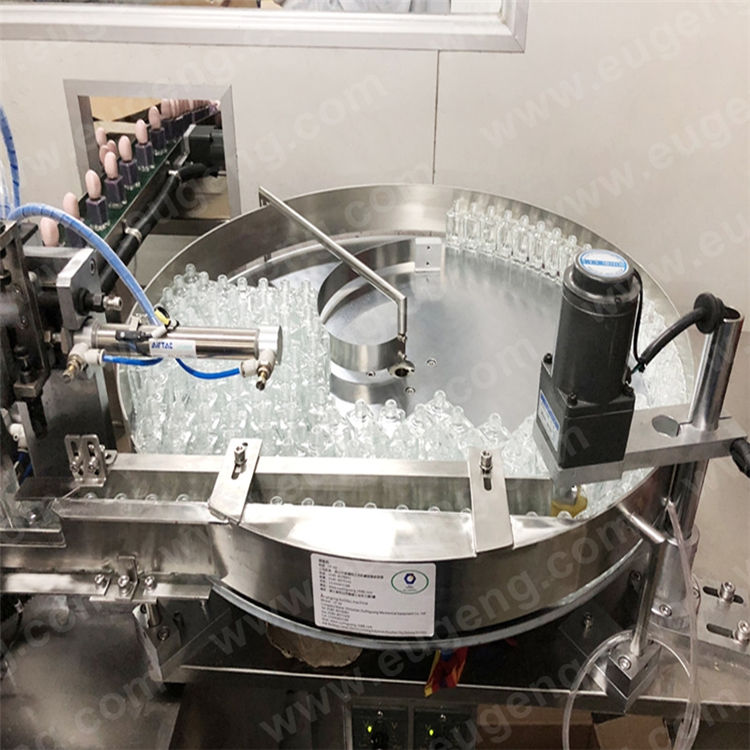

Indexing turn table with 39 bottlers holder, 10 working station

1 set of 60 L pressure tank

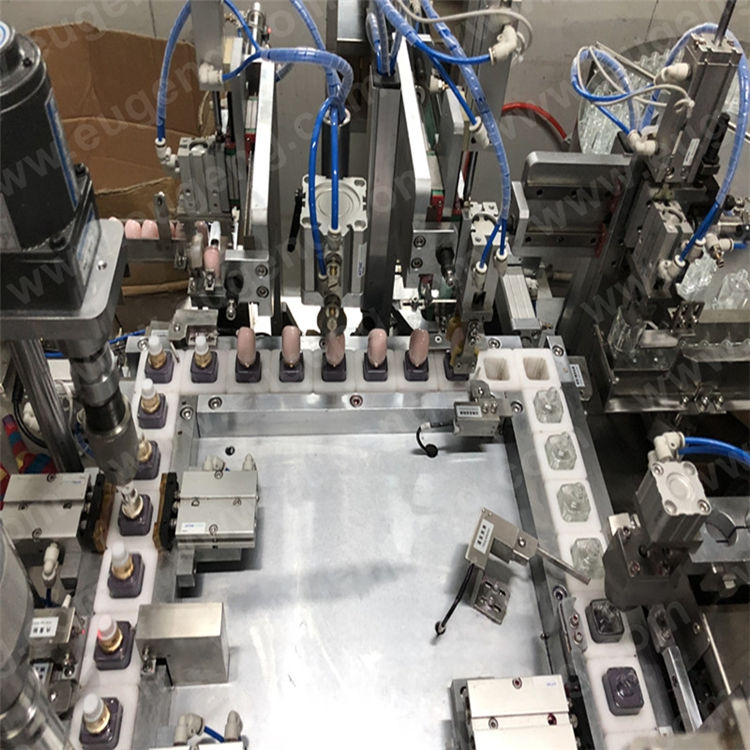

Automatic feeding bottles,fill balls ,loading brush,and cap loading and capping

1 set filling balls unit with automatic by cylinder,and fill 0 / 1 / 2 balls once

Vacuum or piston filling structure for optional

If material with more big glitter ,Suggest use piston filling system

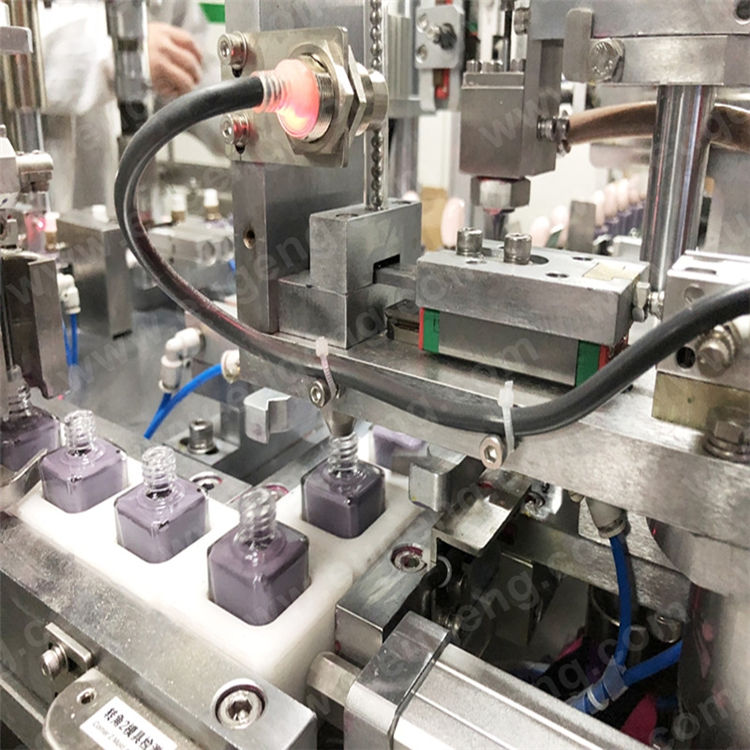

Cap tightening station tightens caps to correct torque by servo motor (you can set the torque through touch screen)

Automatic taking out finished products

nail polish filling and capping machine Capacity

30-35 bottles/min

nail polish filling and capping machine Mold

Nylon pucks (according to different bottle size)

| Model | EGNF-01A |

| Voltage | 220V 50Hz |

| Production type | Push type |

| Output capacity/hr | 1800-2100pcs |

| Control type | Air |

| No. Of nozzle | 1 |

| No. of working station | 39 |

| Vessel volume | 60L/set |

| Display | PLC |

| No. of operator | 0 |

| Power consumption | 2kw |

| Dimension | 1.5*1.8*1.6m |

| Weight | 450kgs |

| Air input | 4-6kgf |

| Optional | Pucks |

Automatic feeding bottles into machine

Automatic filling

Sensor for checking tubes,no tube, no filling

Automatic fill stainless ball

You put your bulk tank into our pressure tank directly

Automatic loading brush

Vibrator feeding the caps

Automatic loading cover cap

Loading inner caps and pre-screw

Screw capping, torques can be adjusted

Automatic take out the finished products

Electric components brand list

| Item | Brand | Remark |

| Touch screen | Mitsubishi | Japan |

| Switch | Schneider | Germany |

| Pneumatic component | SMC | China |

| Inverter | Panasonic | Japan |

| PLC | Mitsubishi | Japan |

| Relay | Omron | Japan |

| Servo motor | Panasonic | Japan |

| Conveyor&mixingmotor | Zhongda | Taiwan |

Product detail pictures:

Related Product Guide:

To create much more benefit for consumers is our company philosophy; customer growing is our working chase for Good Quality Silicone Mold Lipstick Production Line - Nail Polish Filling And Capping Machine – Eugeng , The product will supply to all over the world, such as: panama, Turin, Philippines, To meet the requirements of specific customers for each bit more perfect service and stable quality merchandise. We warmly welcome customers around the world to visit us, with our multi-faceted cooperation, and jointly develop new markets, create a brilliant future!

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.