High definition Tunnel Freezer - Silicone Mold Lipstick Production Line – Eugeng

High definition Tunnel Freezer - Silicone Mold Lipstick Production Line – Eugeng Detail:

Model EG-LIP- 10A lipstick production line includes 3 sets machines

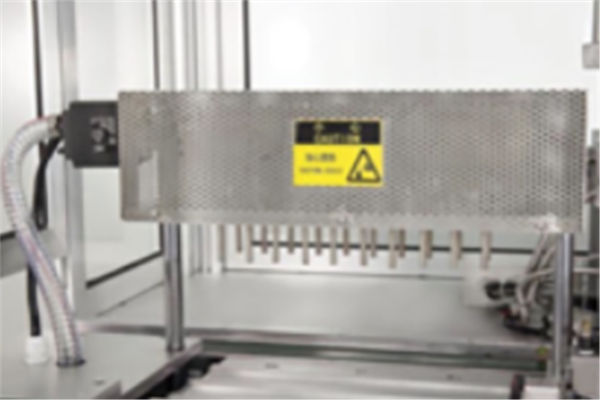

1. AUTOMATIC SILICONE MOULD FILLING MACHINE

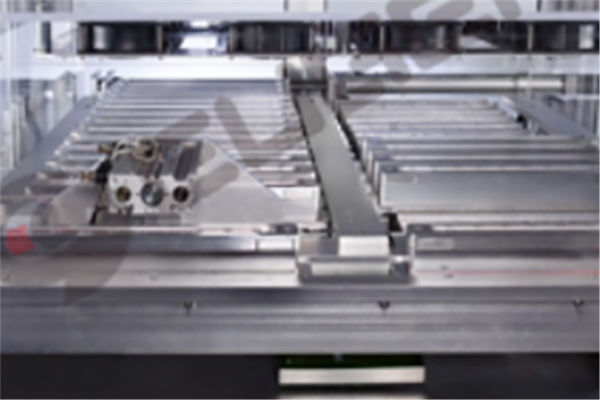

2. AUTOMATIC COOLING TUNNEL

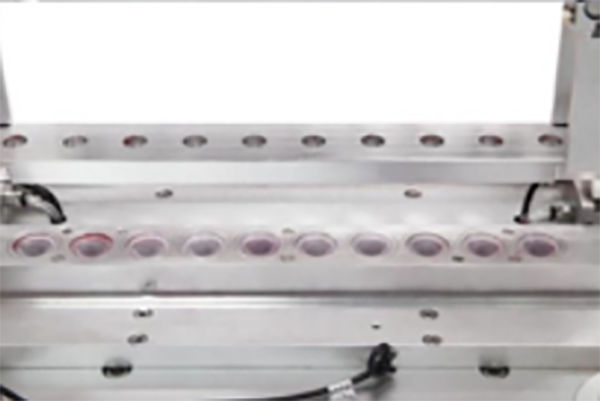

3. AUTOMATIC LIPSTICK RELEASING MACHINE

Silicone molding lipstick,lip pencil

Silicone mold lipstick production line Capacity

40pcs /min (10 nozzle filling heads)

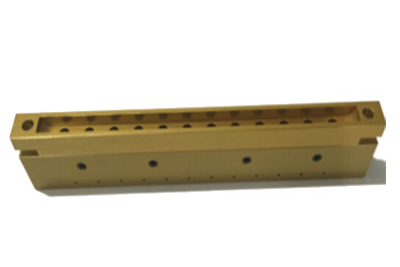

Silicone mold lipstick production line mold

1000pcs Silicone mold and

40pcs silicone mold holder

.2 sets of 3 layers of jacketed vessels 25L capacity with stirrer

· Servo motor controlled dosing pump

· Dosing volume and pump speed controlled by digital input ,Accuracy +/-0.5%

· Filling unit designed for easy strip-down cleaning and re-assembly to facilitate quick

change over

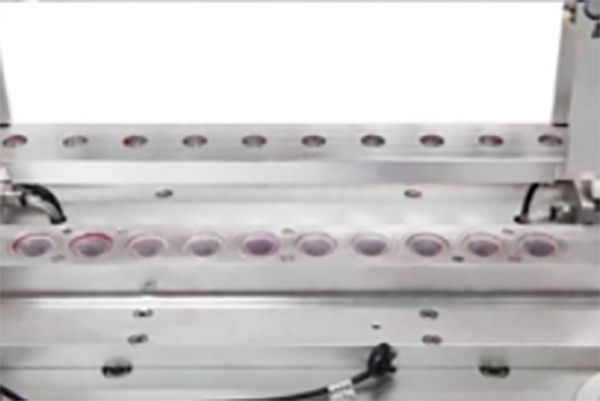

· Mold raise/lower system for bottom-up filling

· Servo controlled mold raise /lower system, speed can be adjusted

· Mold pre and post heating(before and after filling)

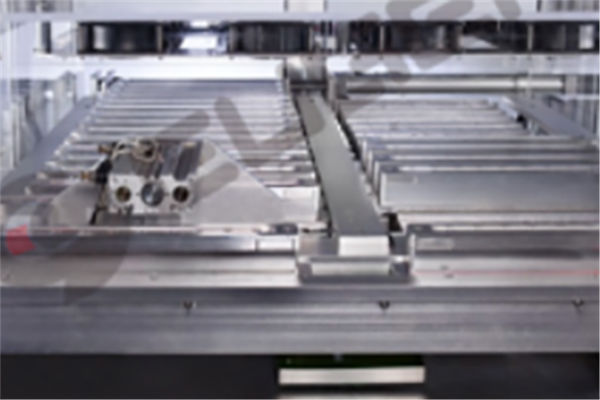

. Cooling tunnel have two tunnel with 4 station stop,

. Automatic frost remove prevent water on the mold

. Stainless steel 304 frame, and spray foam in frame for preventing water

dipping at the door

. Temp control by digital T.I.C, and Min is -20 degree

. Conveyor speed and cooling temp controlled according to the type of product

·Automatic feed mold in/out to discharge conveyor

·Automatic releasing by robot

·Cover of mold be put back with automatic

·Mold recycling with automatic

·Releasing unit designed for easy taking out from mold with back air vacuum

·Operation with digital into by PLC interface.

silicone mold preheating twice

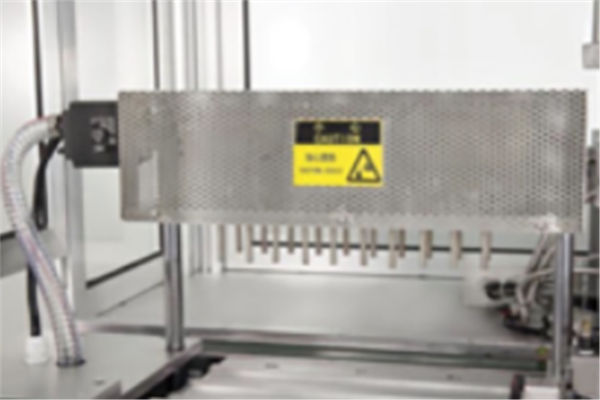

10 filling nozzle , all be heated ,valve box fast cleaning and reassembly

Cooling tunnel with one by one molds

Releasing ,taking out top mold

Automatic robot insert lipstick into case and put back on pucks

Product detail pictures:

Related Product Guide:

We've been commitment to offer the competitive rate ,outstanding merchandise good quality, too as fast delivery for High definition Tunnel Freezer - Silicone Mold Lipstick Production Line – Eugeng , The product will supply to all over the world, such as: Johor, Bahrain, Sierra Leone, We solution have passed through the national skilled certification and been well received in our key industry. Our specialist engineering team will often be ready to serve you for consultation and feedback. We are able to also provide you with no cost samples to meet your needs. Best efforts will be produced to offer you the very best service and solutions. For anyone who is considering our business and solutions, please speak to us by sending us emails or get in touch with us right away. As a way to know our products and enterprise. lot more, you'll be able to come to our factory to find out it. We will constantly welcome guests from around the globe to our firm. o build enterprise. elations with us. Please really feel absolutely free to make contact with us for small business and we believe we will share the top trading practical experience with all our merchants.

The company can keep up with the changes in this industry market, product updates fast and the price is cheap, this is our second cooperation, it's good.