Hot Wax Filling Machine

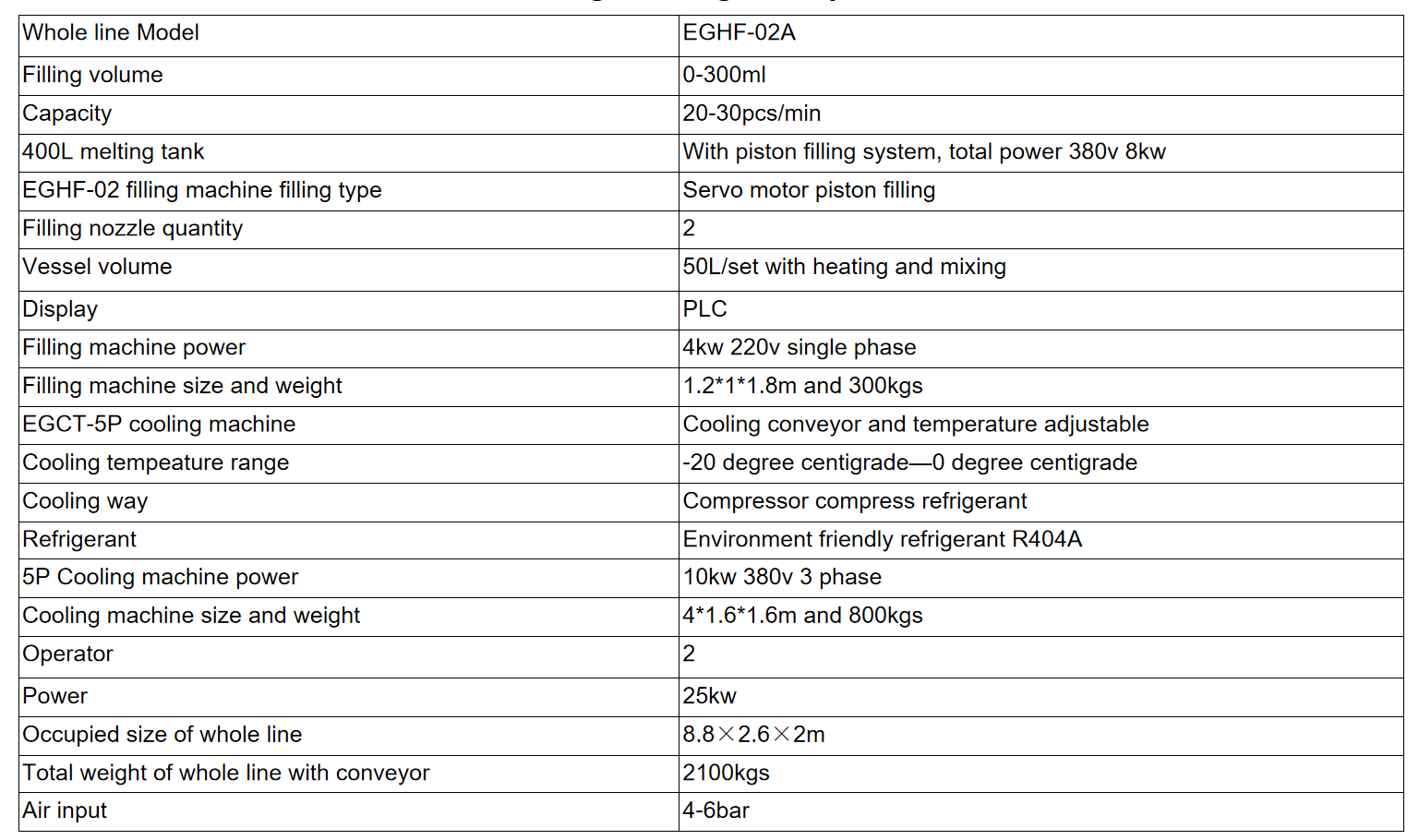

EGHF-02A Hot Wax Filling Machine is a full automatic type hot filling cooling line with automatic capping machine,labeling machine,foil sealing machine as option.

Adopt 2 nozzles Hot filling machine with 50L heating mixing jacket filling tank and 10 Horse power cooling machine to cool whole hot liquid being solid completely after hot filling.

Makeup remover/Cleansing balm

Lip balm tin

Glass bottle wax

Hair wax/Hair pomade

.400L melting tank with pump to feed hot liquid into filling tank directly

.Piston filling system, driven by servo motor, filling speed and volume can be set on the touch screen

.Filling machine has 3 layers 50L jacket heating mixing tank,heating temperature and mixing speed adjustable

.2 filling nozzles,filling 2 pcs once

.Filling volume 0-300ml

.With preheating function,preheating time and temperature can be set as needs

.10 Horse power cooling machine,SUS304 machine cabinet,double-layer heat insulation,ensure no foggy water inside of cabinet

.R404A environment friendly refrigerant, lowest temperature can be -20 degree centigrade

Hot Wax Filling Machine Capacity

.20-30pcs/min

Hot Wax Filling Machine Components Brand

PLC&Touch screen Mitsubishi, Servo motor Panasonic,Switch Schneider,Relay Omron,Pneumatic componets SMC,

Yinghuate compressor,KUBAO control system,Omron relay,Schneider Switch

Hot Wax Filling Machine Optional Parts

.Extra one set of 400L melting tank

.Extra one set of piston with valve

.Automatic lot number or date printing machine

.Automatic screw capping machine

.Automatic labeling machine

.Automatic foil sealing machine

400L melting tank with rotor pump

2 nozzles Filling machine

Melting tank&Filling machine

Filling 2pcs once

Piston filling system,easy cleaning

50L jacket heating mixing tank

Reheating to make top surface flat

Short cooling tunnel with air chiller

10 Horse power cooling machine

11 Loops inside of cooling chamber

Flexible circle conveyor

Customize puck for different bottle