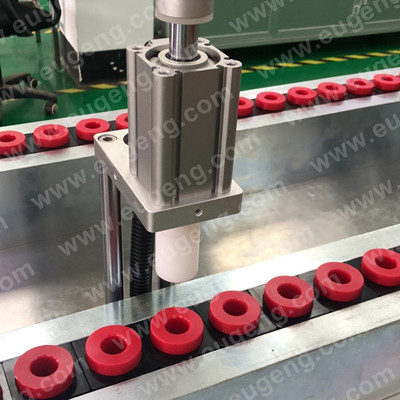

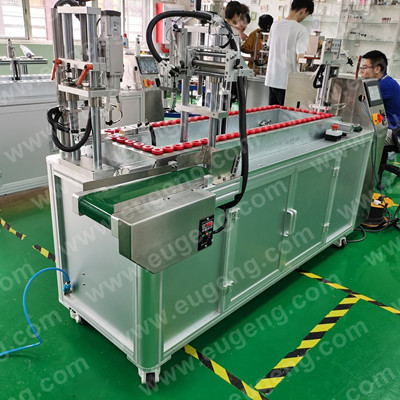

Liquid Lipstick Filling Machine

Liquid Lipstick Filling Machine Detail:

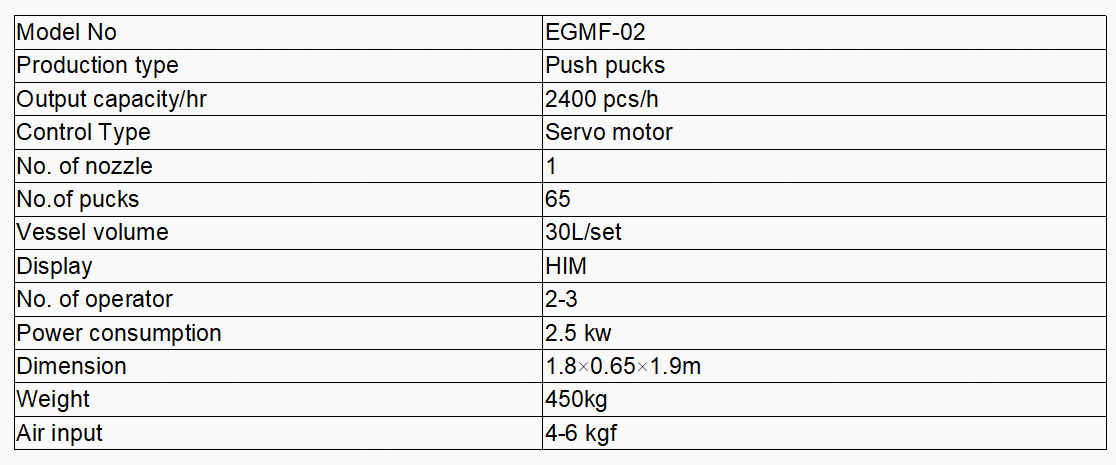

Model EGMF-02 liquid lipstick filling machine is a semi automatic filling and capping machine,push type design with total 65 puck holders,

designed for production of lip gloss,mascara,eyeliner,liquid foundation,Mousse foundation,lip concealer,gel,essential oil etc..

.1 set of 30L pressure tank

.1 set of 60L pressure tank with filling pipe to fill liquid directly from tank(optional)

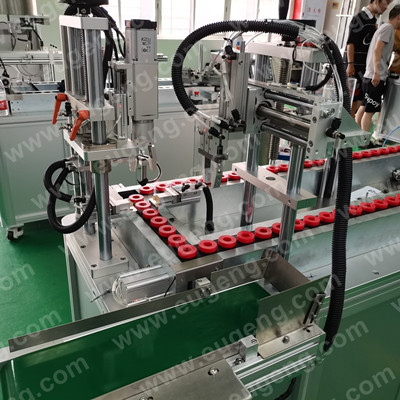

.Piston filling system,easy for color change and cleanning

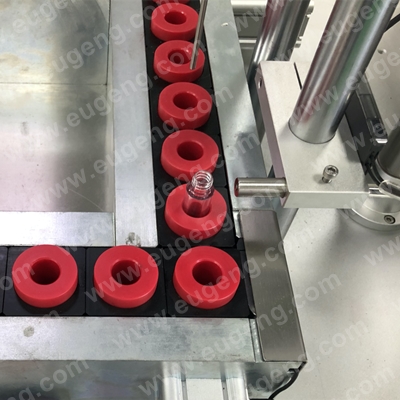

.Auto filling driven by servo motor,while filling while bottle moving down,dosing volume and filling speed adjustable

.High filling accuracy+-0.05g,small volume 1.2ml to 100ml

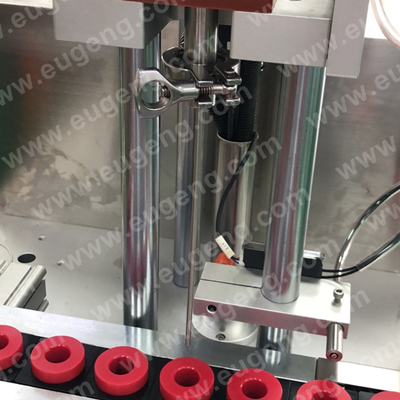

.Put plug by hand and auto plug pressing by air cylinder

.Caps sensor,no cap no capping

.Servo motor control capping,capping torque adjustable

.Auto discharge,picking up finished product into output conveyor

Liquid lipstick filling machine Components brand

.Mitsubishi PLC,touch screen,Panasonic servo motor,Omron Relay,Schneider switch,SMC pneumatic components

Liquid lipstick filling machine Puck holder(Optional)

.POM materials,customized as bottle shape and size

Liquid lipstick filling machine Capacity

.35-40pcs/min

Liquid lipstick filling machine wide application

.For low viscosity and high viscosity liquid

Push type table,65 puck holders Sensor check,no bottle no filling Servo motor filling,filling speed and volume adjustable

Plug pressing by air cylinder Servo motor capping,capping speed and torque adjustable Pressure plate inside of filling tank

60L pressure tank to put in ground Auto discharge,picking up finished products and putting into output conveyor

Product detail pictures:

Related Product Guide:

With our leading technology at the same time as our spirit of innovation,mutual cooperation, benefits and development, we are going to build a prosperous future alongside one another with your esteemed enterprise for Liquid Lipstick Filling Machine , The product will supply to all over the world, such as: Montpellier, Brasilia, Surabaya, Our products are sold to the Middle East, Southeast Asia, Africa, Europe, America and other regions, and are favorably appraised by clients. To benefit from our strong OEM/ODM capabilities and considerate services, please contact us today. We will sincerely create and share success with all clients.

We have been appreciated the Chinese manufacturing, this time also did not let us disappoint,good job!