OEM Customized Lipgloss Label Machine - Horizontal Bottom Labeling Machine – Eugeng

OEM Customized Lipgloss Label Machine - Horizontal Bottom Labeling Machine – Eugeng Detail:

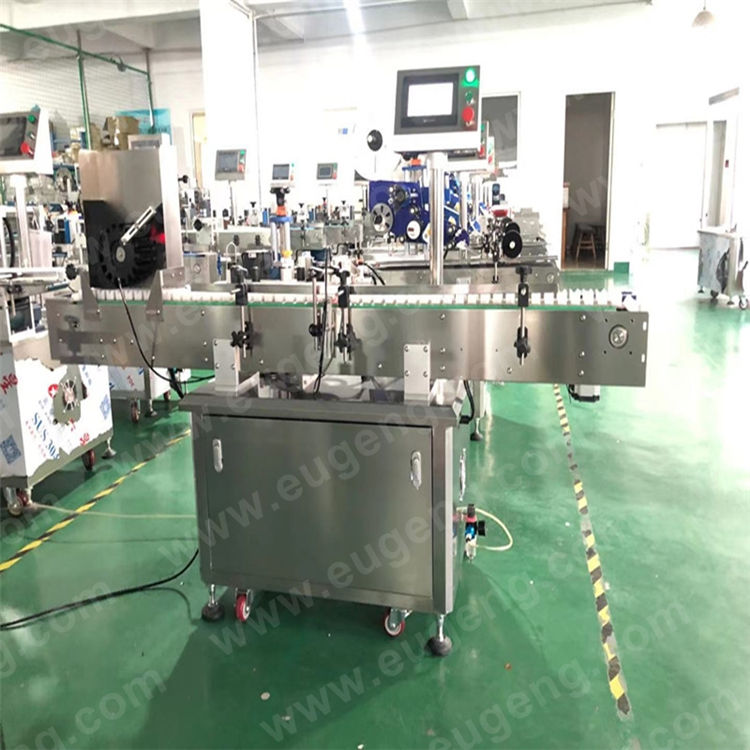

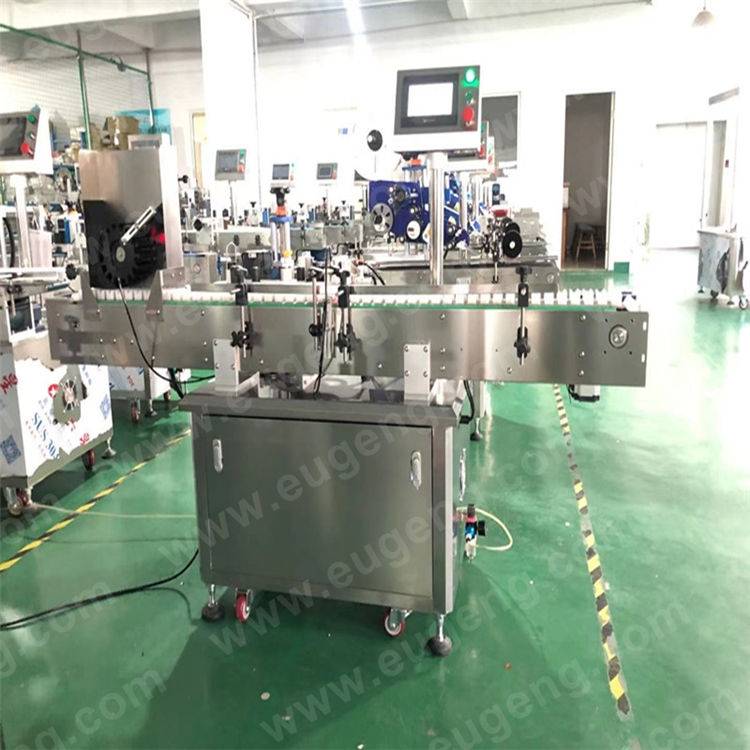

Model EGBL-600 horizontal bottom labeling machine is a semi-automatic horizontal labeling machine design for the production of slim round bottles,tube products,such as lip balm bottles,lip gloss bottles,lipstick bottles,mascara,eyeliner pen and so on.

Mascara bottom labeling

Mascara bottom labeling

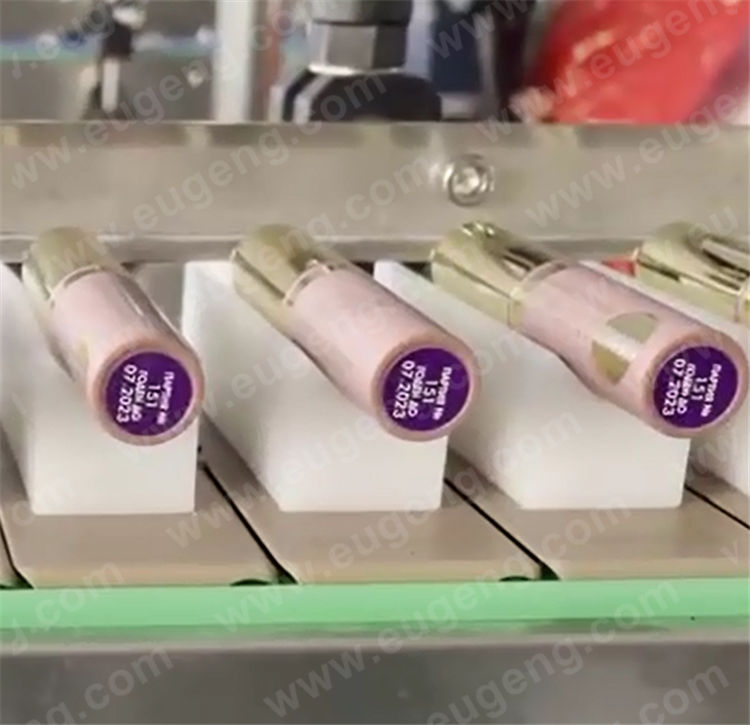

Lip gloss bottom labeling

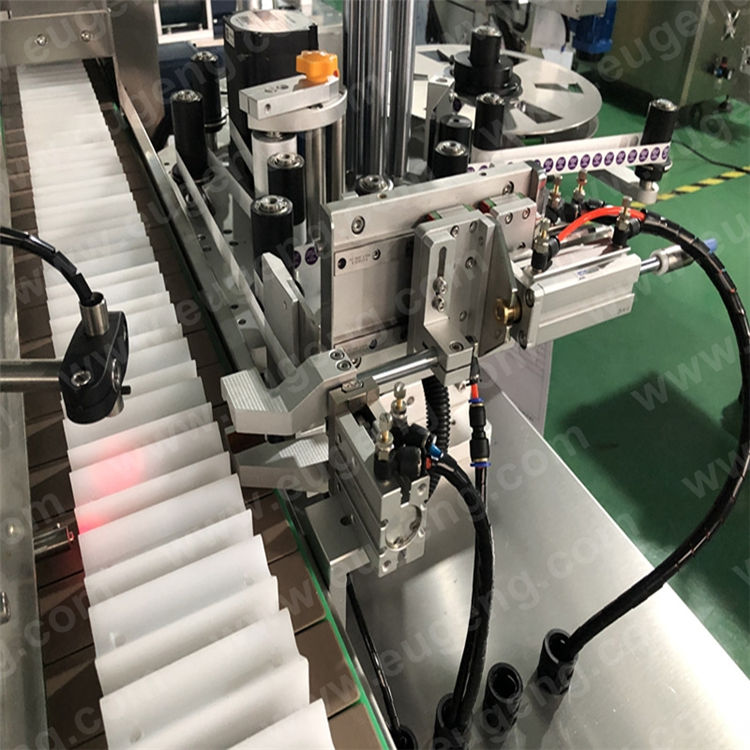

Automatic sensor check , no products, no labeling

Labeling Accuracy +/-1mm

Automatic roll label for prevent missing label

Labeling head X&Y position can be adjusted

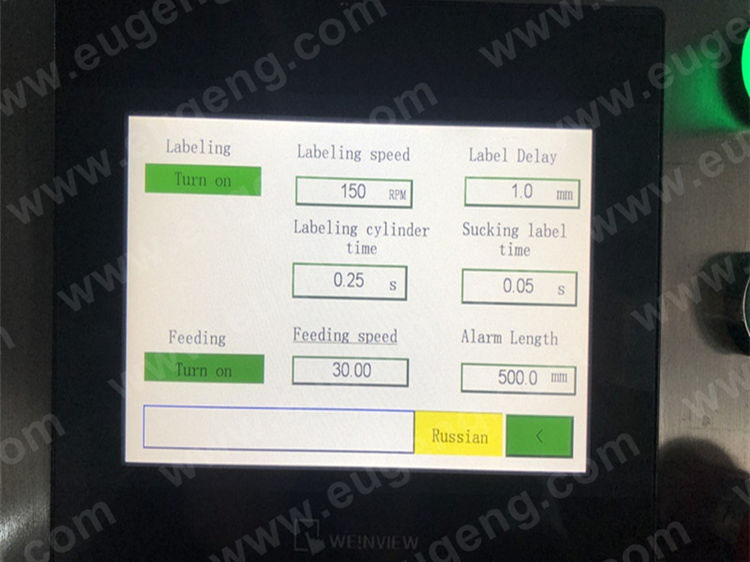

Touch screen operation

Equipped with counting function

Labeling speed,conveying speed and products feeding speed can be set on the touch screen

Label delay length and alarm length can be set on the touch screen

Labeling cylinder time and sucking label time can be set on the touch screen

Language can be customized as user’s language

Product positioning device ensures high labeling accuracy and also higher labeling speed

Horizontal bottom labeling machine Capacity

50-60pcs/min

Horizontal bottom labeling machine Optional

Transparent label sensor

Hot stamping label sensor

| Model | EGBL-600 |

| Production type | Liner type |

| Capacity | 50-60pcs/min |

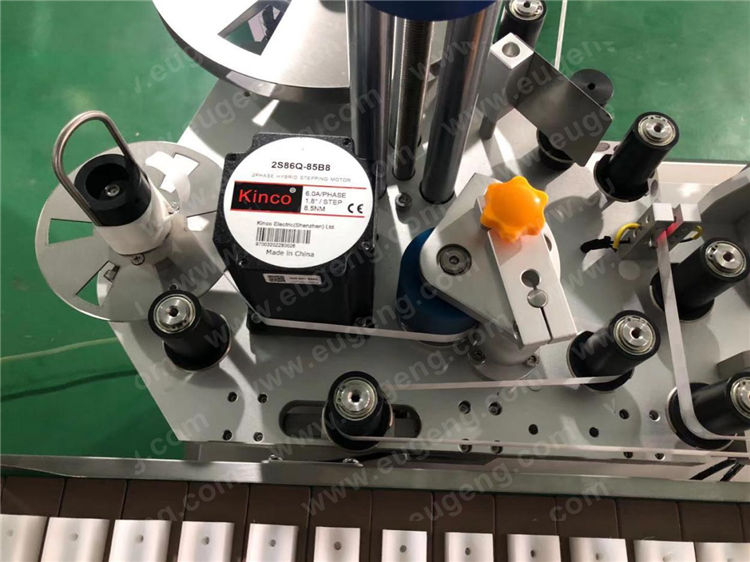

| Control type | stepper motor |

| Labeling accuracy | +/-1mm |

| Label size range | 10«width«120mm,length»20mm |

| Display | PLC |

| No. of operator | 1 |

| Power consumption | 1kw |

| Dimension | 2100*850*1240mm |

| Weight | 350kgs |

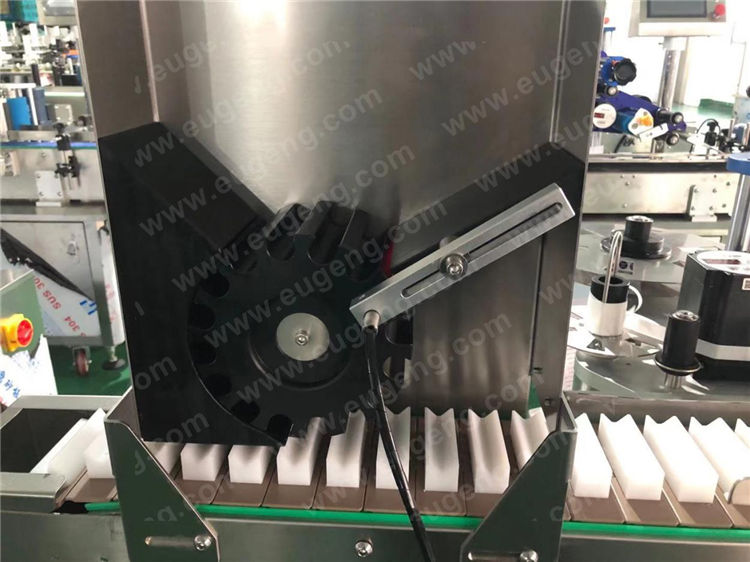

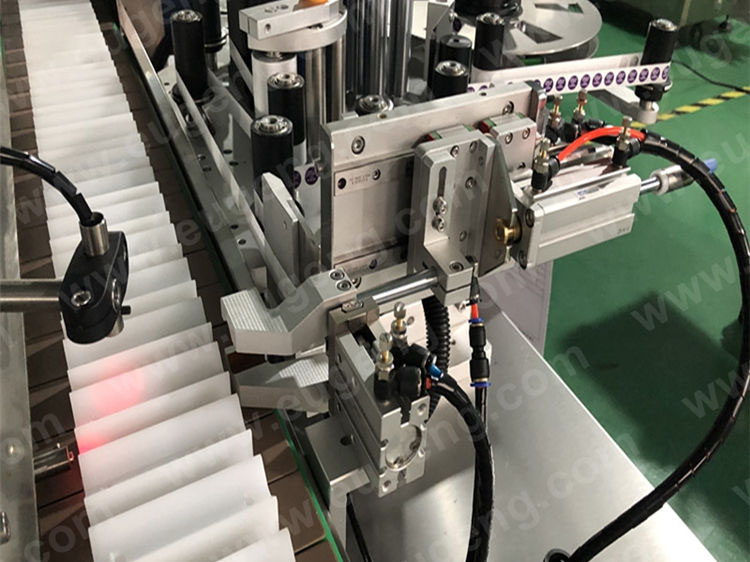

Bottles feeding hopper

Automatic check the label and correct the position

Product sensor

Labeling position can be adjusted

Stepper motor control labeling

Winding roller

PLC MITSUBISHI

Product detail pictures:

Related Product Guide:

It really is our obligation to satisfy your requirements and efficiently serve you. Your fulfillment is our greatest reward. We're hunting forward to your check out for joint development for OEM Customized Lipgloss Label Machine - Horizontal Bottom Labeling Machine – Eugeng , The product will supply to all over the world, such as: Istanbul, Myanmar, Sudan, We are looking forward to establishing a mutually beneficial relationship with you based on our high-quality products, reasonable prices and best service. We hope that our products will bring you a pleasant experience and carry a feeling of beauty.

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!