OEM/ODM Factory Eyeliner Jar Filling Machine - Push Type Mascara Filling Machine – Eugeng

OEM/ODM Factory Eyeliner Jar Filling Machine - Push Type Mascara Filling Machine – Eugeng Detail:

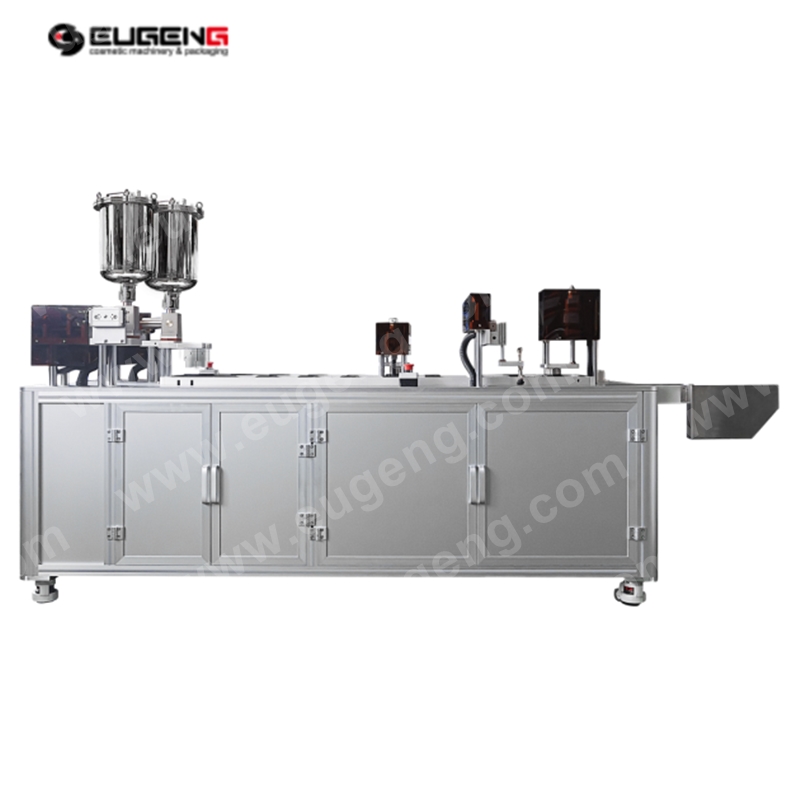

Model EGMF-02 mascara filling machine is a semi-automatic filling and capping machine design for the production of lip gloss,mascara eyeliner,nail polish,cosmetic liquid foundation,perfume card,teeth whitening pen etc..suitable for filling both liquid and high viscosity paste gel ,filling and capping round bottles,square bottles and some irregular bottles.

Lip gloss

Mascara

Eyeliner

·1 set 30L pressure tank with inner plug for high viscosity materials

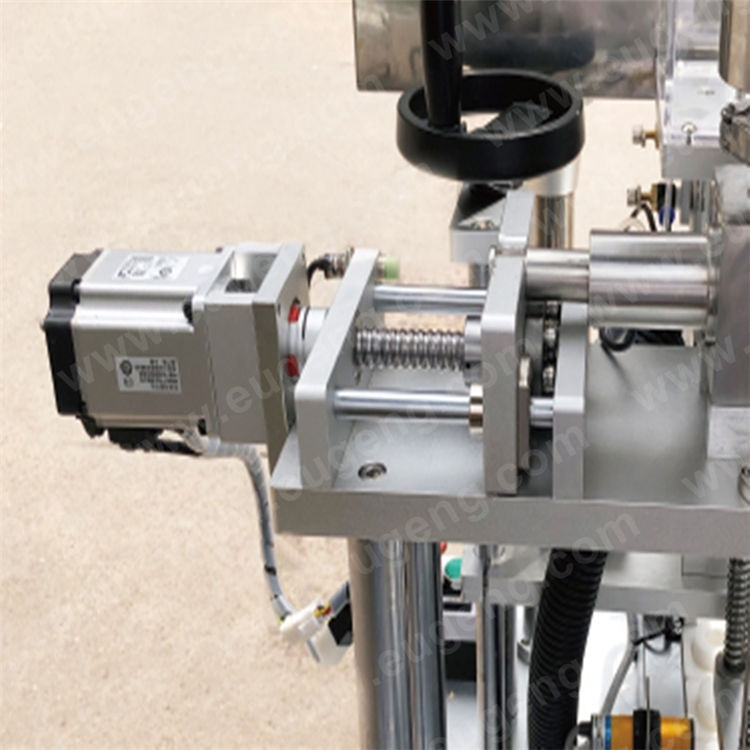

· Piston controlled dosing pump, and with servo motor driving , filling while tube moving down

. Machine with sucking back function so that prevent dripping

·Accuracy +/-0.5%

·Filling unit designed for easy strip-down cleaning and re-assembly to facilitate

quick change over

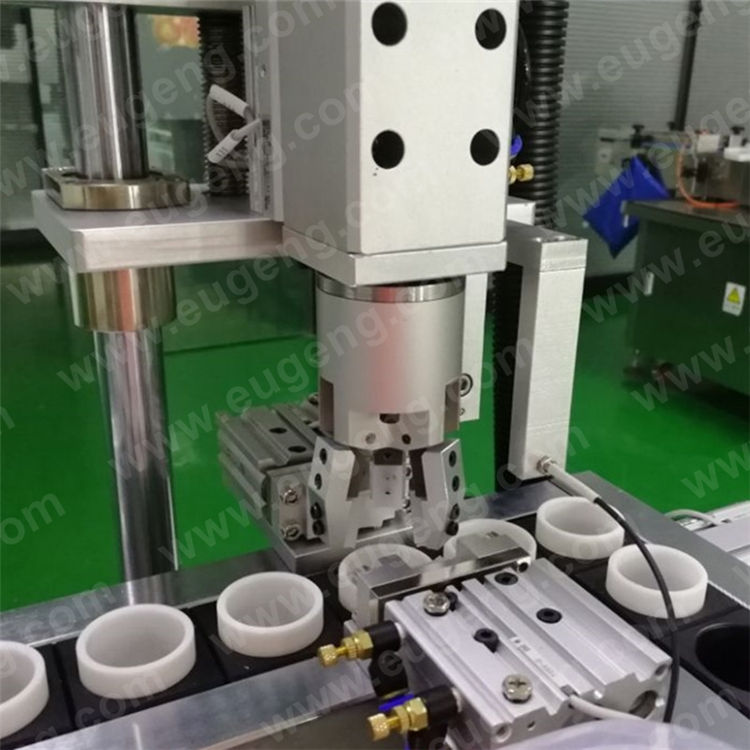

·Servo-motor capping unit with adjusted torque,capping feed and capping height also adjustable

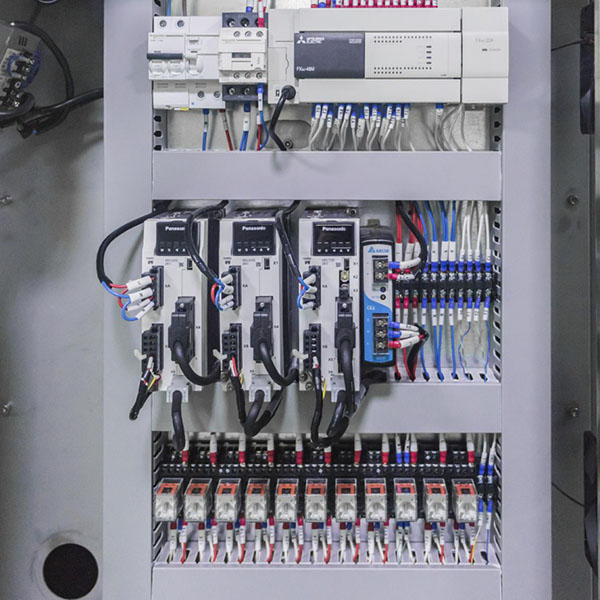

·Touch screen control system with Mitsubishi brand PLC

Servo motor Brand:Panasonic Original: Janpan

Servo motor control the capping , and torques can be adjusted , and reject rate is less than 1%

mascara filling machine wide application :

Widely used for filling lip gloss,mascara,eyeliner,nail polish,cosmetic liquid foundation,serum,essential oil,perfume,teeth whiten gel etc..

mascara filling machine Mold customized

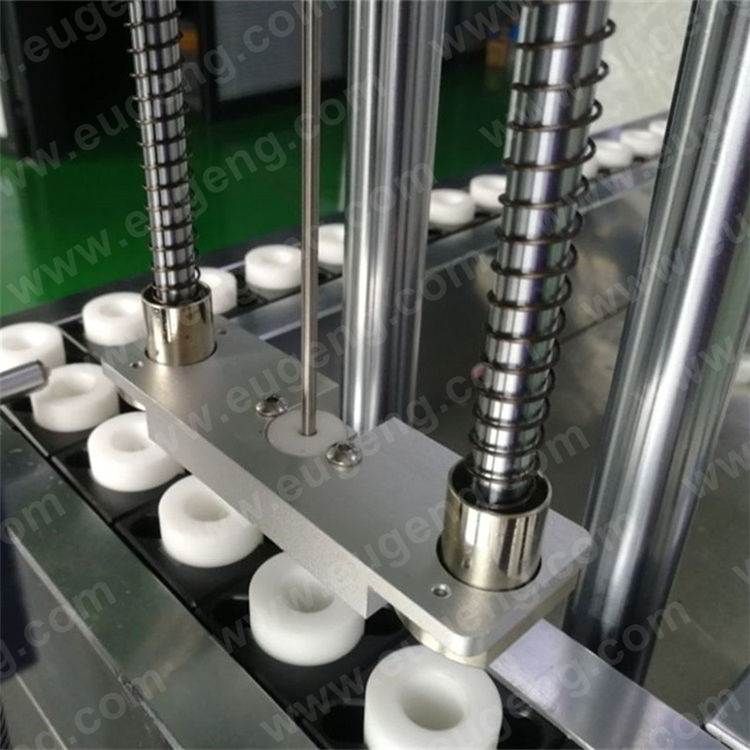

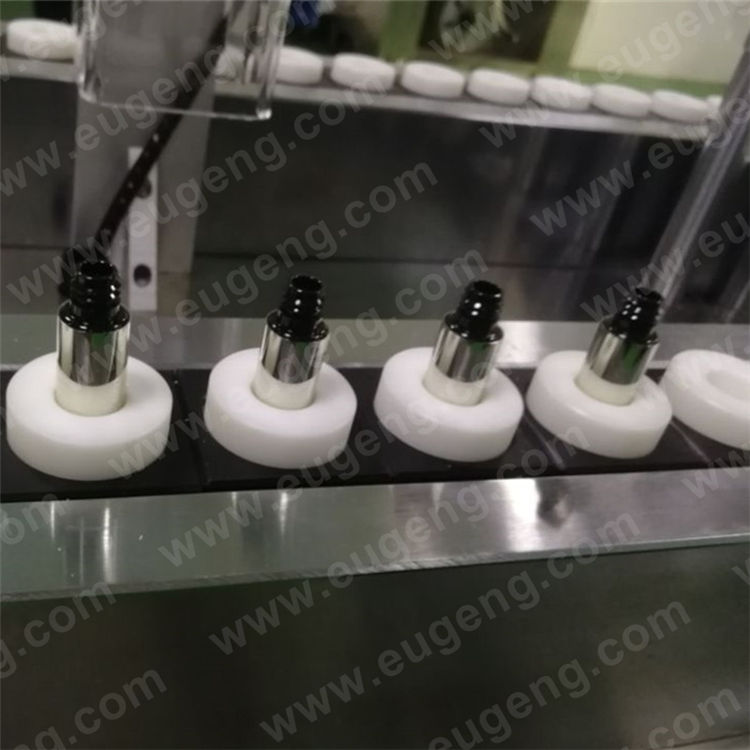

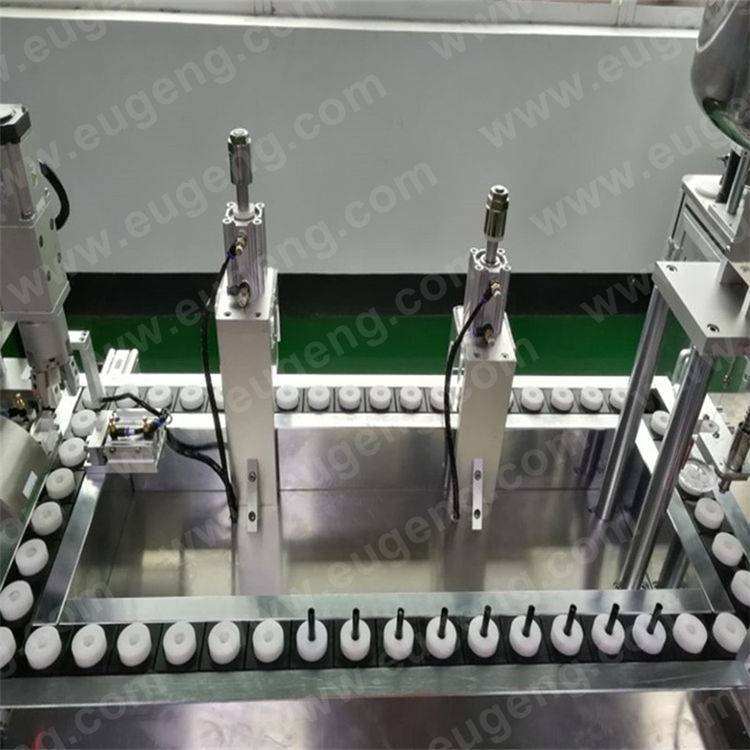

Nylon holder(according to the diameter of bottle)

Lip gloss mascara filling machine Capacity

30–35pcs/min

| Model | EGMF-02 |

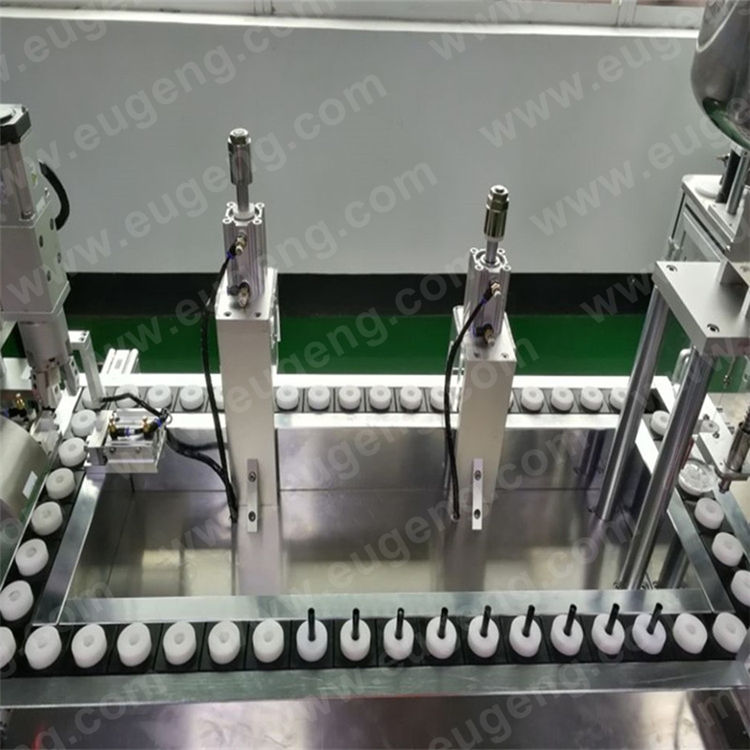

| Production type | Push Pucks |

| Output capacity/hr | 1800-2100pcs/h |

| Control type | Servo motor&Air Cylinder |

| No.of Nozzle | 1 |

| Number of pucks | 49 |

| Vessel volume | 30L/set |

| Display | PLC |

| No.of operator | 2-3 |

| Power consumption | 2.5kw |

| Dimension | 1.5*0.8*1.9m |

| Weight | 450kg |

| Air input | 4-6kgf |

Push Table

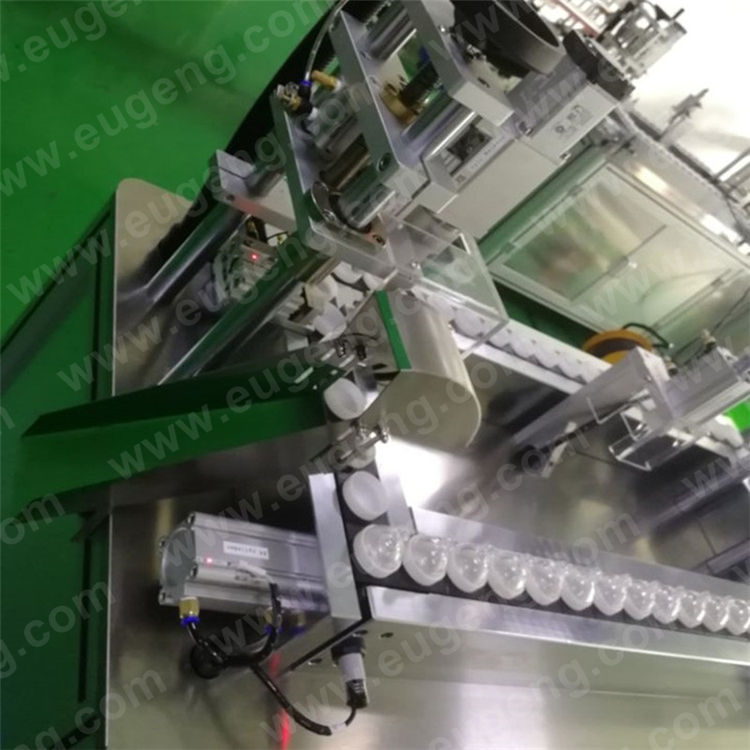

Sensor for checking tubes no tube no filling

Filling nozzle with guider prevent nozzle broken

Pressure tank with plug for high viscosity bulk

Filling system fast cleaning and reassembly

Filling with servo motor driven, volume adjustable

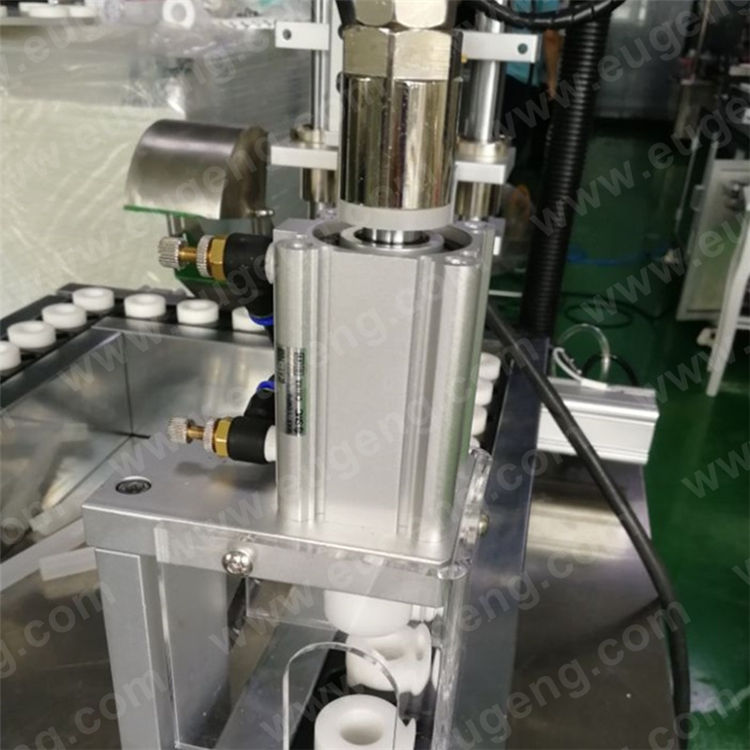

Pressing wiper with cylinder,can turn on/off

Servo motor capping , torques can be adjustable

Capping head height can be easily adjusted

Different size tube just need change pucks

Filling stainless ball

PLC Mitsubishi

Servo Motor Panasonic

Pneumatic is SMC

Product detail pictures:

Related Product Guide:

From the past few years, our firm absorbed and digested sophisticated technologies equally at home and abroad. Meanwhile, our organization staffs a group of experts devoted into the growth of OEM/ODM Factory Eyeliner Jar Filling Machine - Push Type Mascara Filling Machine – Eugeng , The product will supply to all over the world, such as: Philadelphia, Paris, United Arab Emirates, After 13 years of researching and developing products, our brand can represent wide range of products with outstanding quality in world market. We have completed big contracts from many countries such as Germany, Israel, Ukraine, United Kingdom, Italy, Argentina, France, Brazil, and so on. You probably feel secure and satisfy when copperate with us.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.