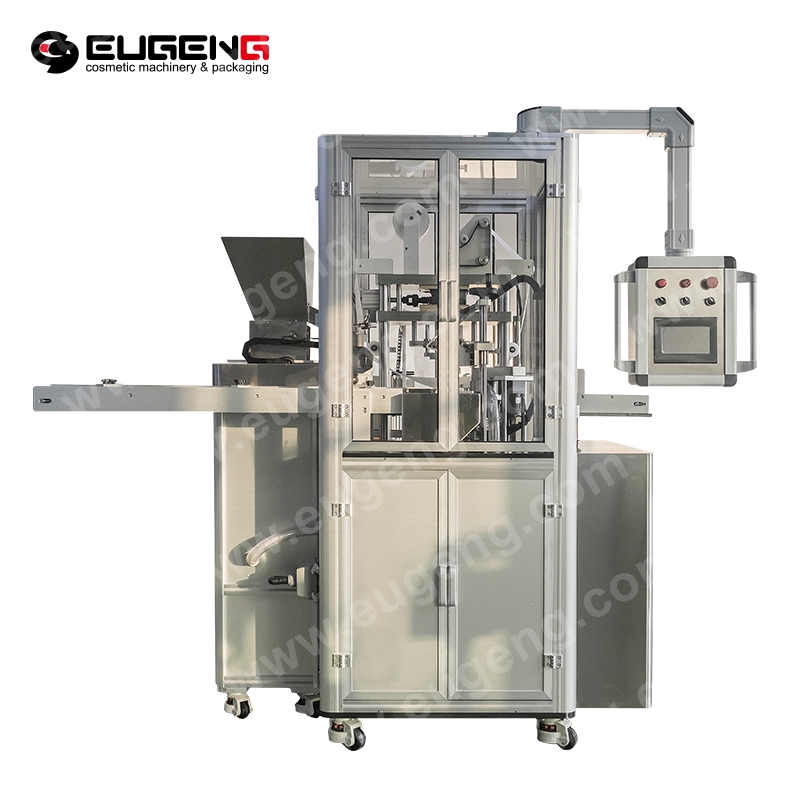

Reasonable price Cosmetic Tunnel Freezer - Silicone Mold Lipstick Production Line – Eugeng

Reasonable price Cosmetic Tunnel Freezer - Silicone Mold Lipstick Production Line – Eugeng Detail:

Model EG-LIP- 10A lipstick production line includes 3 sets machines

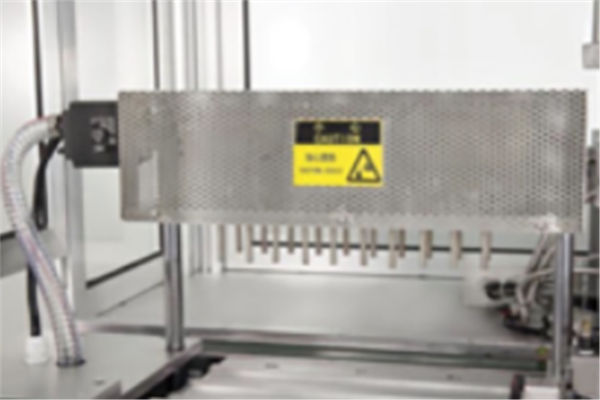

1. AUTOMATIC SILICONE MOULD FILLING MACHINE

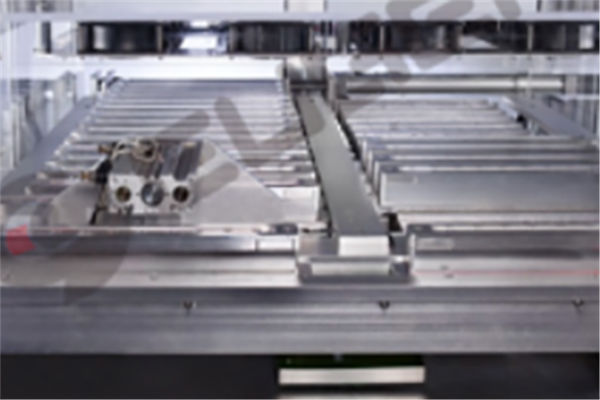

2. AUTOMATIC COOLING TUNNEL

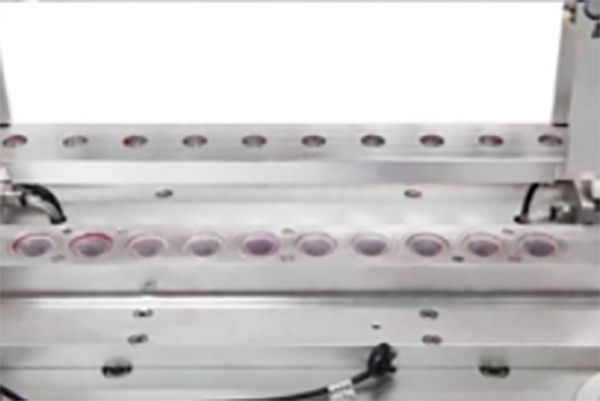

3. AUTOMATIC LIPSTICK RELEASING MACHINE

Silicone molding lipstick,lip pencil

Silicone mold lipstick production line Capacity

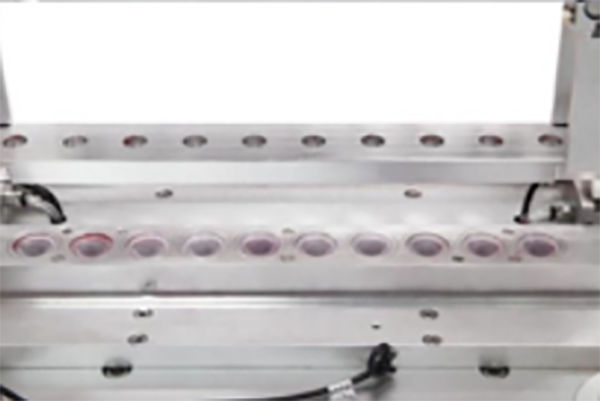

40pcs /min (10 nozzle filling heads)

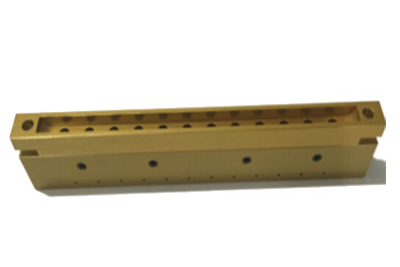

Silicone mold lipstick production line mold

1000pcs Silicone mold and

40pcs silicone mold holder

.2 sets of 3 layers of jacketed vessels 25L capacity with stirrer

· Servo motor controlled dosing pump

· Dosing volume and pump speed controlled by digital input ,Accuracy +/-0.5%

· Filling unit designed for easy strip-down cleaning and re-assembly to facilitate quick

change over

· Mold raise/lower system for bottom-up filling

· Servo controlled mold raise /lower system, speed can be adjusted

· Mold pre and post heating(before and after filling)

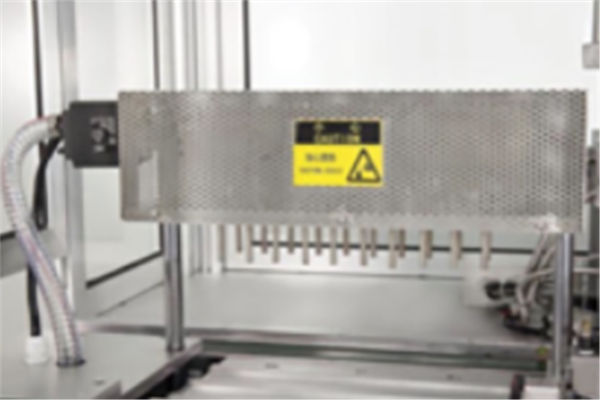

. Cooling tunnel have two tunnel with 4 station stop,

. Automatic frost remove prevent water on the mold

. Stainless steel 304 frame, and spray foam in frame for preventing water

dipping at the door

. Temp control by digital T.I.C, and Min is -20 degree

. Conveyor speed and cooling temp controlled according to the type of product

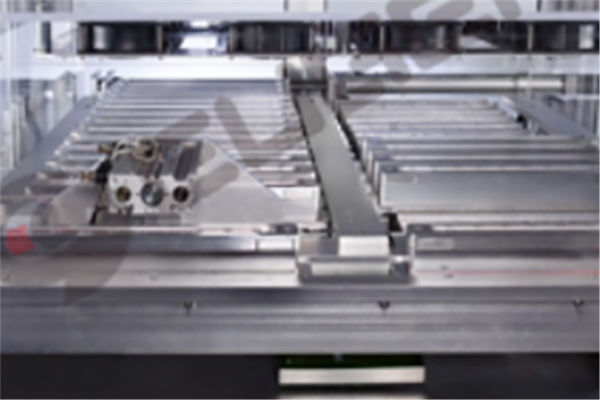

·Automatic feed mold in/out to discharge conveyor

·Automatic releasing by robot

·Cover of mold be put back with automatic

·Mold recycling with automatic

·Releasing unit designed for easy taking out from mold with back air vacuum

·Operation with digital into by PLC interface.

silicone mold preheating twice

10 filling nozzle , all be heated ,valve box fast cleaning and reassembly

Cooling tunnel with one by one molds

Releasing ,taking out top mold

Automatic robot insert lipstick into case and put back on pucks

Product detail pictures:

Related Product Guide:

Adhering into the theory of "quality, services, efficiency and growth", now we have gained trusts and praises from domestic and international shopper for Reasonable price Cosmetic Tunnel Freezer - Silicone Mold Lipstick Production Line – Eugeng , The product will supply to all over the world, such as: Bangladesh, Bandung, Congo, Now, we are trying to enter new markets where we do not have a presence and developing the markets we have the already penetrated. On account of superior quality and competitive price , we will be the market leader, please don’t hesitate to contact us by phone or email, if you are interested in any of our products.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!